The Role of the Cable Jacket for Medical Cables: Part 4 – Skin Contact and Material Selection, Cleaning and Disinfection, Sterilization

Skin Contact and Material Selection

ISO 10993 and FDA regulations call for materials used in medical devices which come in contact with the body to be biocompatible. Dorland’s Medical Dictionary defines biocompatible as “The quality of not having toxic or injurious effects on biological systems.”

By their nature, most patient cables come in contact with the body and therefore should employ medical-grade, biocompatible materials. Because all of the common materials used for medical cable jackets are available in medical grades, meeting biocompatibility requirements does not limit material selection.

Cleaning and Disinfection

The cable jacket plays a large role in determining what methods can be used to clean and disinfect a cable.

ANSI/AAMI EC53 established minimum standards for cleaning and disinfection of ECG Cables and Leadwires. Section 4.3.1 of the standard details cleaning and disinfection requirements with the following solutions:

- green soap or alcohol-free hand soap

- 2% glutaraldehyde solution (such as Cidex)

- Sodium hypochlorite (bleach) solution 10% in water

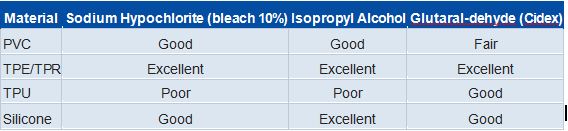

In addition, because it is commonly found in clinical settings, alcohol based solutions are often used. The following table offers guidance in the selection of both cable jacket and overmold resins based on how the cable assembly will be cleaned or disinfected:

Sterilization

|

|

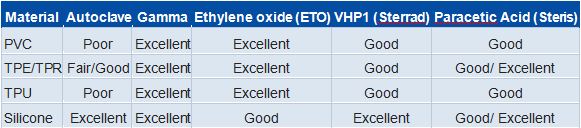

When the elimination of all micro-organisms by sterilization is required, the selection of a suitable cable jacket material becomes even more significant. Of the three most common methods: steam autoclave, low-temperature hydrogen peroxide (Sterrad®) or peracetic acid (Steris®), steam autoclave is the most challenging for many materials used for cable jackets and overmolding.

Of the materials commonly used for medical cable jackets, only silicone can withstand hundreds of autoclave cycles.

The following table may assist in the selection of both cable jacket and overmold material based on which common sterilization method will be employed:

Summary

The Affinity engineering team has decades of experience designing medical cable assemblies, including recommendations for cable construction and jacket material. Our team can help match your mechanical and electrical performance requirements with an ascetically pleasing appearance and tactile feel.

If you would like to take advantage of Affinity’s experience and expertise in providing robust, long lasting cable assemblies, we welcome you to contact us at +1 949-477-9495 or via email to CustomerCare2@Affinitymedical.com.

Silicone jacketed cables can withstand

Silicone jacketed cables can withstand